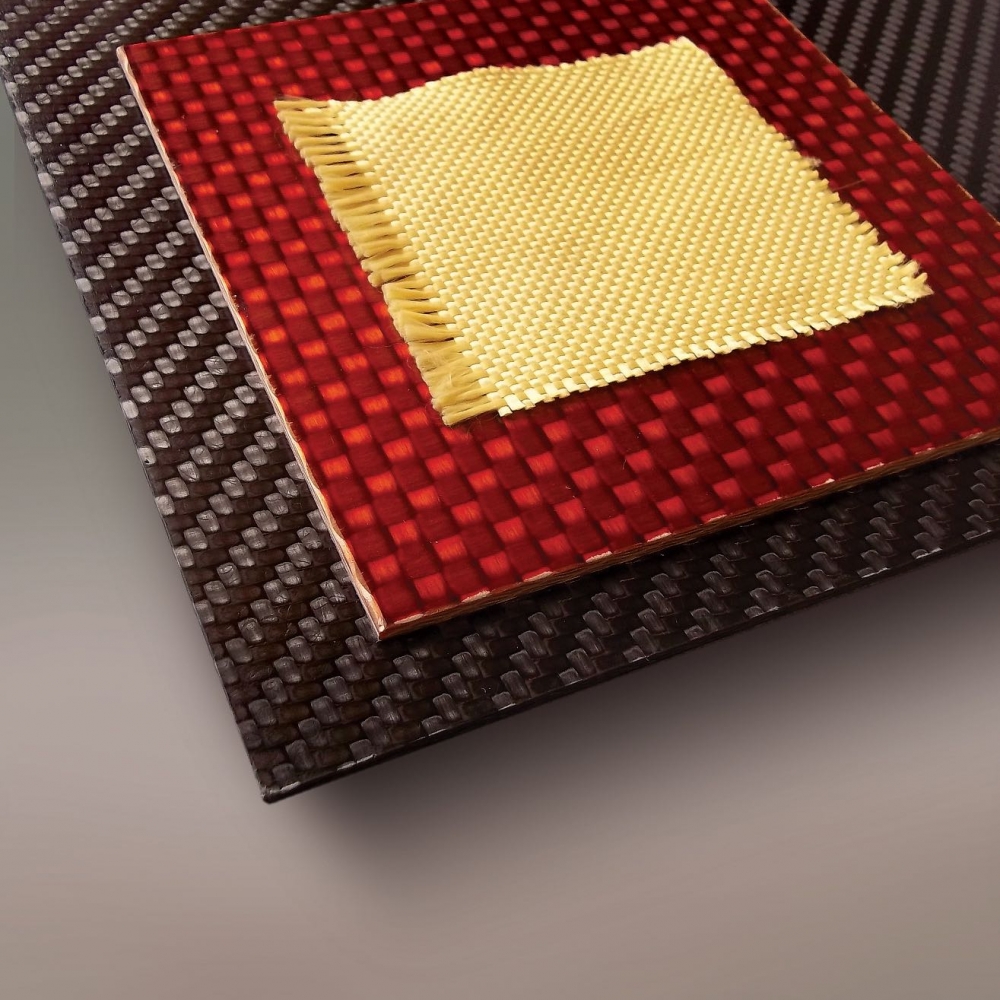

Prepreg Materials

Prepregs are fabrics, tissues or other reinforcement materials which are pre-impregnated with resin to form semi-cured products that are used for moulding of advanced composite parts and reinforced tubes.

Micam develop customised prepreg solutions to match the material properties and processing requirements of our customers. We have impregnation capability for epoxy, silicone, melamine, phenolic and polyester resins onto a variety of reinforcement materials such as glass fabrics, carbon fibre, Kevlar, cotton and nylon. Our prepregs are used in a diverse range of applications such as electrical insulation, micro-electronics, anti-ballistic and construction applications.

MICAM produce a range of semi-cured epoxy prepreg materials suitable for use as a bonding media or for subsequent winding to produce reinforced tubes.

| Type | ||

|---|---|---|

| TG43-7 | Flame retardant FR4 type epoxy- medium weave glass prepreg | |

| TG43-5 | Flame retardant FR4 type epoxy fine weave glass prepreg | |

| TG42 | High temp class F epoxy-glass prepreg | |

| TG46 | General purpose G-10 type epoxy-glass prepreg | |

| CC40 0.2 | Tacky epoxy-glass prepreg 0.2mm thickness | |

| CC40 0.1 | Tacky epoxy-glass prepreg 0.1mm thickness |

MICAM, as a leading manufacturer of prepregs for composite armour manufacture, offers a choice of fibre /resin combinations to suit a wide range of performance requirements and manufacturing methods.

Thermoplastic modified epoxy based systems have been developed by MICAM offering excellent adhesion to ceramic plates or other substrates for personal body armour applications demanding the highest levels of protection.

Phenolic resins are the most widely used resin systems in armour applications. The phenolic matrix can be modified by addition of thermoplastic to produce systems which are combined with aramid or nylon for the manufacture of helmets and personal body armour.

Systems of lower flexibility are recommended for applications where less complex shapes or sheets are required.

Specifically chosen resin systems offer good structural integrity with S-2 Glass, E-Glass and Aramid reinforcements.

Micam develop customised prepreg solutions to match the material properties and processing requirements of our customers. We have impregnation capability for epoxy, silicone, phenolic and polyester resins onto a variety of reinforcement materials such as glass fabrics, carbon fibre, Kevlar, cotton and nylon. Our prepregs are used in a diverse range of applications such as electrical insulation, micro-electronics, anti-ballistic and construction applications.